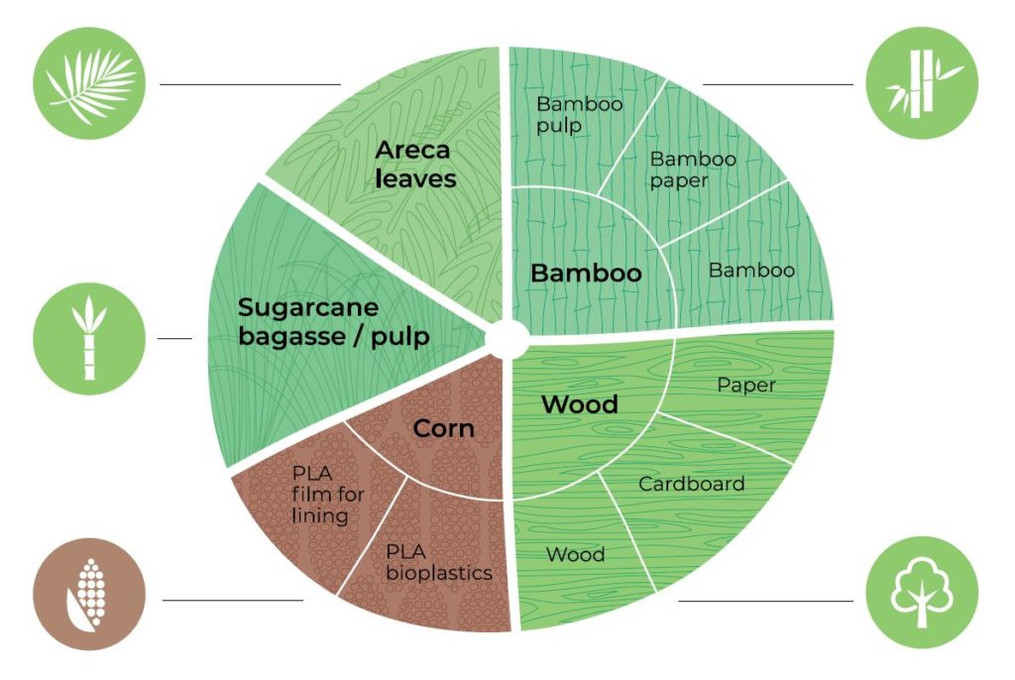

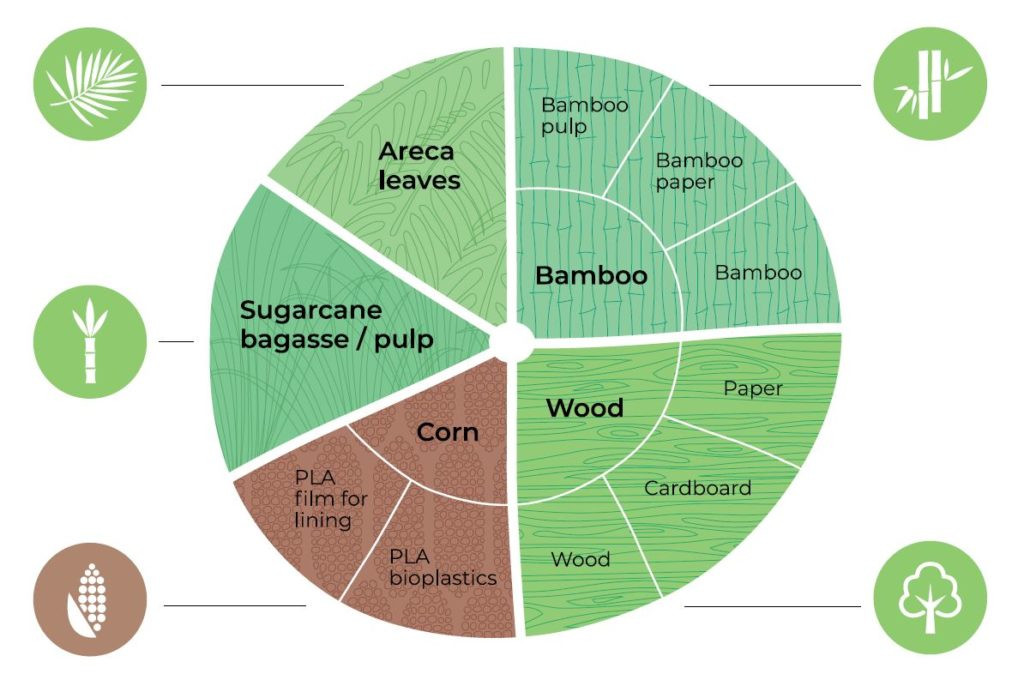

Eco Materials: Which Should I Use?

19th Nov 2019

So many different plant-based ‘plastics’ are floating around the market. But how do you know what you’re actually using, and why you should use one over the other? Here we provide brief profiles for several common materials, so you can understand what you’re buying.

Sugarcane Bagasse / Pulp

Bagasse is the waste material from sugarcane processing. Sugarcane bagasse is the dry fibrous residue left over once sugarcane stalks are crushed and the juice extracted for sugar manufacturing. Because the fibres are already crushed, we need less energy to make products from bagasse compared to pulping wood for paper. Bagasse products are strong, durable, and pleasant to touch. Even without lining, sugarcane pulp is leak- and oil-proof. You can use it to store food in the fridge and warm up food in the microwave, but don’t microwave cook with it. This material is ISO 9001 and ISO 14000 certified. End of life: Recyclable (in the paper stream) and compostable. Made to decompose in a commercial composting facility in 60-90 days, but also suitable for home composting. Complies with ASTM D6868 and EN13432 reports for compostability.

Areca Palm Leaves

Areca palms drop their leaves regularly, which can be made into plates and bowls. Areca trees have large fronds which fall to the ground every couple of weeks. Rather than them being collected and burnt, the usual approach, they can be turned into disposable bowls, plates, and platters – natural, degradable, and compostable. These leaves are strong, semi-flexible (but not brittle), water- and heat-resistant, and odourless. To add to their charm, they have a characteristic texture and colour, and each one is unique. They can tolerate microwave cooking and even oven baking. To create a bowl, plate, or platter, the leaves are washed and heat-pressed (for sterilisation) into the desired shape. They do not require pulping or starching. It is a completely natural process. End of life: Use again or compost. If you don’t have a compost bin at home, you can break the plate up and spread the pieces around your garden. In breaking down they will enrich the soil like any other leaf within a few months.

Bamboo / Pulp / Paper

Bamboo is one of the fastest-growing plants in the world. Bamboo is very fast growing, and is therefore a relatively sustainable choice. They can grow at up to 91 cm a day, which makes them one of the fastest-growing plants on earth. They need no irrigation or replanting after their harvest every 3-5 years. This means products made from bamboo are usually FSC certified. End of life: Recyclable and compostable. Be aware: some bamboo coffee cups are lined with PLA lining (see below) and can be composted in industrial composting facilities only. Given that Australia and New Zealand currently have limited accessible composting facilities (see our post on BioPak's initiative in Canberra for how this is changing), these cups are better put into paper recycling.

Cardboard

Cardboard is a renewable resource if made from wood grown in well-managed plantations. Cardboard is a renewable resource in properly managed plantations, and production emissions are decreasing. Cartons are usually manufactured from wood fibre. End of life: Cartons can be collected and recycled to form a secondary raw material. This is usually through reprocessing in a mill to separate the fibres, which are then used to make carton board or another paper or board product. They can also be composted or used to make power in an energy-from-waste incinerator.

PLA Biobased Plastics

PLA bioplastics are made from corn and are biodegradable. PLA, a bioplastic made from corn, is a common material in clear cups and cutlery. Producing PLA requires fewer greenhouse gas emissions compared to traditional, oil-based plastics. Please note: keep PLA bioplastics clear of heat sources or direct sun. They are very heat sensitive and must be stored below 35oC. End of life: PLA bioplastics can be composted in industrial composting facilities only, an option not yet widely available in Australia or New Zealand.

PET Recyclable Plastics

PET plastics are recyclable; however, recycling should be a last resort. While oil-based, PET plastics are an efficient packaging material due to its strength, meaning that more product can be put in less packaging and suppliers save on fuel costs during transport. PET has a more sustainable production cycle compared to glass and other plastics. Please note: use PET products for cold food only. End of life: Recycle in plastic stream. However, recycling is a high-energy process, and should be used as a last resort. In addition, considering the current state of recycling in Australia, it is best to use compostable materials.

All information taken from http://www.greenmarkpack.com.au/materials/. For more business sustainability information, head to our blog.